Exploring the Uses of Membrane Switch Over in Various Industries

Membrane buttons are indispensable components throughout numerous sectors, including customer electronic devices and automotive markets. Their light-weight and durable nature enables reliable use in compact gadgets. On top of that, these buttons provide resistance to environmental aspects, boosting their long life. As industries evolve, the demand for customizable remedies grows. This raises essential inquiries concerning the future applications and technologies of membrane layer button modern technology. What brand-new opportunities exist ahead for this flexible element?

Membrane Layer Changes in Customer Electronics

Membrane layer buttons play an essential role in consumer electronics, providing a reliable user interface for numerous tools. These buttons are made to be slim and lightweight, making them perfect for modern gadgets where room goes to a costs. Their adaptability enables assimilation right into diverse products, ranging from home home appliances to handheld devices. The responsive comments provided by membrane layer switches over improves individual interaction, ensuring a seamless experience.Moreover, membrane layer buttons are resistant to moisture and dirt, which is vital for keeping capability in daily environments. They can be customized with numerous graphics and colors, enabling producers to straighten with branding demands. In addition, the cost-effectiveness of membrane layer button innovation makes it a preferred selection for mass-produced electronic devices. As consumer need for streamlined, straightforward gadgets continues to expand, the importance of membrane layer switches in delivering trusted, effective interfaces comes to be increasingly noticeable, strengthening their location in the electronics market.

Applications in the Automotive Industry

In the vehicle industry, membrane layer switches are made use of to improve both capability and appearance within cars. These switches are commonly integrated right into dashboards, control board, and infotainment systems, supplying a modern and smooth user interface for passengers and vehicle drivers. Their design enables for smooth integration with different materials, which contributes to the total visual allure of the vehicle's interior.Furthermore, membrane switches are valued for their durability and resistance to ecological aspects such as moisture, temperature level, and dust fluctuations. This makes them optimal for applications in auto setups, where reliability is essential. Furthermore, they can be personalized with numerous graphics and formats, permitting manufacturers to create one-of-a-kind branding elements and user experiences.As automotive innovation remains to evolve, the demand for innovative control solutions will likely drive even more improvements in membrane switch applications, ensuring they stay a vital element in contemporary car layout.

The Duty of Membrane Layer Switches Over in Health Care

Although usually forgotten, the function of membrane buttons in health care is necessary for making sure the effective operation of medical tools and tools. These switches serve as customer interfaces for a range of applications, including analysis devices, patient surveillance systems, and medical instruments. Their layout enables for easy cleansing and sterilization, which is essential in preserving hygiene in clinical environments.Membrane switches are additionally understood for their resilience and resistance to put on, making them suitable for devices that sustain frequent usage. Their tactile responses offers customers with a trustworthy experience, enhancing use for health care specialists. Additionally, membrane layer switches can be tailored with various graphics and designs, ensuring that they satisfy specific demands of various medical applications. Generally, the integration of membrane buttons in healthcare innovation not just improves performance yet also adds to person safety and functional performance within medical facilities.

Aerospace Innovations With Membrane Layer Switch Over Technology

Industrial Automation and Membrane Change Solutions

Membrane layer button modern technology is increasingly finding applications in industrial automation, where dependability and effectiveness are extremely important. These buttons act as integral components in different automated systems, facilitating individual communications in settings that require effectiveness and durability. Their design permits a seamless integration with control panels and equipment, ensuring ease of use for operators.In industrial settings, membrane layer buttons can hold up against rough problems, consisting of direct exposure to dust, wetness, and extreme temperatures. This resilience makes them ideal for applications in production, logistics, and procedure control. In addition, their adjustable functions allow companies to create customized options that satisfy particular operational needs.The responsive responses supplied by membrane layer changes boosts user experience, lowering the probability of mistakes throughout operation - membrane switch. As industries proceed to site here advance in the direction of greater automation, the duty of membrane layer switch technology is anticipated to broaden, driving efficiencies and boosting operations in complicated industrial atmospheres

Often Asked Inquiries

What Products Are Commonly Utilized in Membrane Change Building And Construction?

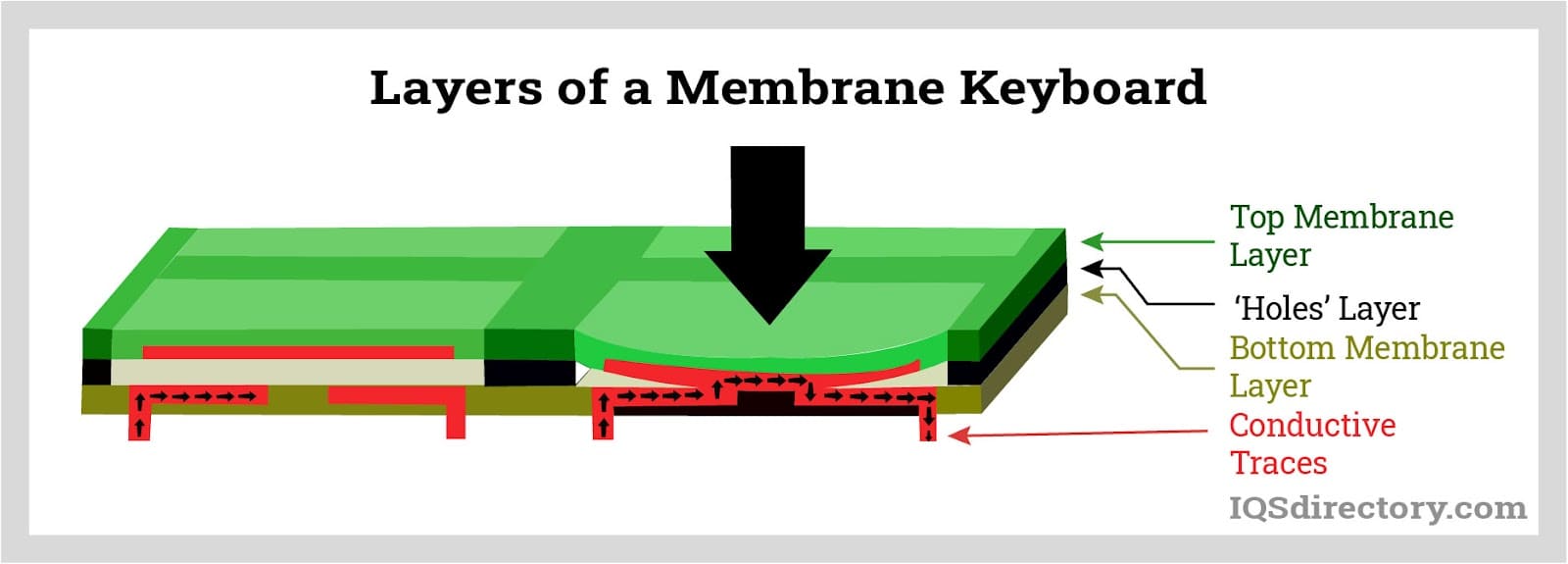

The materials commonly used in membrane button building and construction consist of polyester, polycarbonate, glue layers, published graphics, and conductive inks. These elements ensure responsiveness, versatility, and sturdiness, making them ideal for visit the site different digital applications in diverse industries.

How Do Membrane Layer Changes Compare to Traditional Buttons in Toughness?

Membrane switches typically supply remarkable sturdiness compared to typical switches, as they are much less susceptible to mechanical deterioration. Their secured style safeguards versus dust and dampness, improving longevity in numerous applications.

Can Membrane Layer Switches Over Be Custom-made for Particular Applications?

Membrane layer switches can indeed be customized for details applications. Their style flexibility permits tailored shapes, performances, graphics, and dimensions, making them appropriate for varied environments and improving customer interaction throughout numerous electronic gadgets and machinery.

What Are the Environmental Factors To Consider for Membrane Layer Change Disposal?

The environmental factors to consider for membrane layer switch disposal consist of prospective dangers from products utilized, recycling opportunities, and adherence to guidelines. membrane switch. Correct disposal approaches are important to minimize eco-friendly influence and promote sustainability within manufacturing processes

Just How Do Membrane Layer Switches Impact User Experience in Tools?

Membrane layer switches over greatly enhance individual experience with responsive responses, durability, and design versatility. Their seamless combination right into gadgets promotes instinctive communications, while their visual allure can boost item discussion, inevitably adding to customer satisfaction and engagement. The responsive responses provided by membrane layer switches over boosts customer communication, making certain a smooth experience.Moreover, membrane layer switches are resistant to moisture and dust, which is important for keeping capability in day-to-day atmospheres. In addition, membrane buttons can be tailored with numerous graphics and designs, making sure that they satisfy particular requirements of various clinical applications. Membrane layer switches are also immune to wetness and pollutants, guaranteeing resilience and long life in numerous cockpit and cabin applications. Membrane button innovation is increasingly finding applications More about the author in commercial automation, where dependability and efficiency are extremely important. Membrane layer switches typically supply remarkable sturdiness compared to standard switches, as they are much less susceptible to mechanical wear and tear.